Head Health Challenge III

National Institute of Standards and Technology (NIST)

Summary

NIST and Under Armour joined with General Electric (GE) and the National Football League (NFL) on Head Health Challenge III with the goal of spurring the creation of innovative impact-absorbing materials that will result in increased protection for athletes, warfighters and civilians. The challenge partners understood that experts who could produce better materials could be found in a hugely diverse set of communities, from aerospace to automotive to sports medicine. The national prize competition sought to advance research and technology development in this field by gaining the attention of a wide network of materials scientists and others with an interest in answering this call to action.

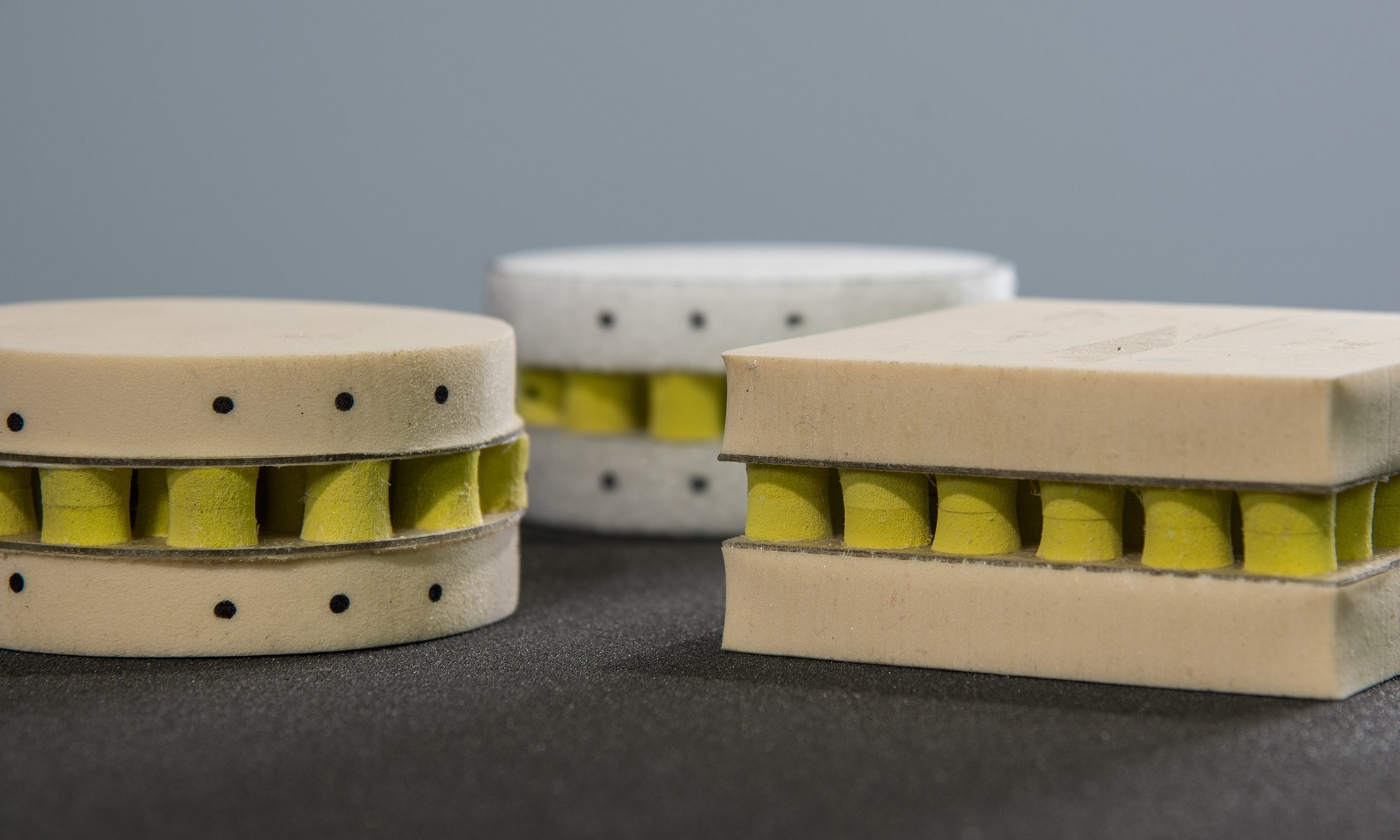

Samples of the winning material from Head Health Challenge III, a partnership between NIST, Under Armour, GE and the NFL. (Photo by Webber & Stoughton/NIST)

Together, the challenge partners decided to reward designers with up to $2 million in prizes to develop innovative materials that could meet technical criteria outlined by the challenge sponsors in this specific question:

"Can your material withstand a force range of up to 12 kilonewtons, with the potential to withstand 1,200 impacts above 20 KE (J), and perform in the impact velocity range of 3.4 m/s to 11.2 m/s, and in temperatures ranging from 0 to 40 degrees Celsius, with up to 100 percent humidity?"

These parameters translate into real-world use: a broad range of impact conditions from youth leagues to the highest level of professional sports, temperature extremes from freezing to a hot summer day, and a year's worth of repeated impacts. The challenge partners worked closely to set the technical requirements and overall vision.

One of the barriers to innovation in helmet design has been a lack of data about how well new substances absorb the force of hits to the head. Improved data helps helmet manufacturers understand if the risk of developing and manufacturing a helmet with a new material will give them an advantage over their competitors in terms of performance. It is particularly difficult to test how materials perform in real-world conditions, such as when they are compressed and flexed by the forces of a hit on a playing field or a blast in combat. Small and medium-sized companies often don't have the capital to develop in-house testing facilities or pay for testing, or the in-house expertise to develop new test methods.

NIST's participation in Head Health Challenge III helped provide the community with this testing infrastructure. NIST has a long history of producing best-in-the-world materials science measurements, and working with the private sector to help define industry parameters for protective helmets and body armor for law enforcement through private-sector led standards. Building on these capabilities, NIST applied its technical expertise to build materials testing instruments in the laboratory and even created a new test in support of the Head Health Challenge III. As NIST learned during the competition, one of the major benefits reported by participants was the opportunity to have their materials assessed by NIST experts.

Head Health Challenge III had multiple phases spanning over two years. The challenge was hosted by NineSigma under contract with NFL, Under Armour and GE. The challenge kicked off Feb. 2, 2015, with an invitation for participants to submit an abstract that described a novel material that met specific performance criteria.

In April 2015, the authors of the top-rated abstracts were invited to submit a more detailed proposal along with samples of the material for testing. Considering the results of mechanical tests performed by NIST and the attributes of the overall proposal, a panel of expert judges identified five teams to be recognized with a first round award of $250,000 each. These first round winners were announced Dec. 15, 2015. Over the next year and a half, the teams further developed their materials in consultation with the challenge partners. In September 2017, the judges selected one grand prize winner to receive $500,000.

Results

NIST's experts conducted a series of impact and compression tests on each sample, as well as on some conventional impact-absorbing materials currently used in helmets to establish a baseline. The NIST tests involved a considerable amount of customization to equipment to subject the materials to the impact energies and velocities that have been reported in different sports and defined in protective equipment standards. Based on written proposals and test results generated by NIST, the panel of expert judges identified five first round winners to receive $250,000 and the opportunity to compete for the grand prize. The first round winners included teams from academic institutions and businesses:

- Alba Technic, LLC (Winthrop, Maine) developed a patented, shock-absorbent honeycomb material with an outer layer that diverts the energy from a fall or hit;

- Charles Owen Inc. (Lincolnton, Ga.) made cellular structures that use a stacked, origami-like design to optimize energy absorption;

- Corsair Innovations (Plymouth, Mass.) developed a textile that uses tiny, spring-like fibers to repel rotational and linear impacts, thereby reducing potential damage;

- Dynamic Research Inc. (Torrance, Calif.) and 6D Helmets LLC collaborated to evolve 6D's single-impact suspension technology for use in repeated impact conditions; and

- University of Michigan (Ann Arbor, Mich.) researchers designed a lightweight, multi-layered composite that includes a viscoelastic material.

After the final testing round, the judges evaluated each Head Health Challenge III participant on innovation, material performance, degree of improvement during the challenge, and commercialization potential, emphasizing creativity over product maturity. In September 2017, NIST announced the team led by Dynamic Research Inc. as the Head Health Challenge III grand prize winner.

The Dynamic Research team received a cash prize of $500,000 to help them progress their product toward commercialization. The team, which includes members from 6D Helmets, used advanced computer modeling and a series of iterative improvements to create a novel material, based on a 6D Helmet proprietary technology with an unusual geometric structure. The winning entry reduced certain measures of impact by more than 70 percent when compared with baseline foam material that has been commonly used in protective gear, and the material's middle layer of absorbent posts sandwiched between foam helps reduce the shear forces that can cause rotational injuries. The winning concept also can be fine-tuned to a variety of impact environments and adapted to different body types and applications.

The challenge yielded benefits for all involved. The finalists reported that they benefitted from their participation in the Head Health Challenge III in many ways. For example, they found they could adjust material to meet a wide variety of impact scenarios, making it possible to expand into new product lines and markets. They attracted commercial partners for further development of their material and integration into helmets and pads for further testing. Participants also reported that they integrated their novel material into an existing product. They verified that industrial 3D printing, also known as additive manufacturing, could be used to make their novel material that will be incorporated into a new product. They also worked with a major materials manufacturer to develop and combine materials for optimum performance, and now have patents pending.

NIST invested more than $1 million in personnel and technical equipment to test the materials samples of the challenge competitors. NIST has identified key measurement needs through its connection with the partners and competitors in the challenge. These needs are driving NIST to develop new methods to assess material response to shearing and rotational impacts, which account for a considerable percentage of brain injuries. These new methods were essential for assessing the materials submitted during the challenge and will be leveraged for future research in the field.

Areas of Excellence

Area of Excellence #1: "Build a Team"

Head Health Challenge III bridged resources through a public-private partnership with the challenge partners consisting of NIST, NFL, Under Armour and GE. This public-private partnership approach leveraged the best of the public and private sectors to solve a pressing problem that would have been hard for any one group to solve on its own. The combination of partners was essential in bringing together technical expertise with a deep knowledge of the realistic need and environmental scenarios for new head health materials.

NIST was asked to become a partner in Head Health Challenge III because of its long history of finding new ways of measuring known substances and systems with ever more precision and accuracy, and creating ways of characterizing novel substances and systems for the first time. The challenge was an opportunity for NIST to expand its measurement capabilities in materials science, in direct support of the organization's mission to promote U.S. innovation and industrial competitiveness. The partners worked together to identify the vision and technical criteria for the challenge, and each contributed funds for the cash prizes. The Challenge was hosted by NineSigma under contract with NFL, Under Armour and GE. Mechanical testing was designed and performed by NIST.

Area of Excellence #2: "Manage the Judging Process and Select Winners"

A panel of independent judges made all decisions about the finalists and the grand prize winner. The director of NIST appointed the judges based on nominations generated by the four challenge partners. This panel of judges, listed below, represented unique and world-class materials expertise from industry, academia and the federal government:

- Jeff Crandall, Ph.D., professor in engineering and applied aciences at the University of

- Virginia

- Sharon Glotzer, Ph.D., professor of chemical engineering at the University of Michigan

- Heinrich Jaeger, Ph.D., professor of physics at the University of Chicago

- Michael Maher, program manager for the Defense Sciences Offices at the Defense

- Advanced Research Projects Agency (DARPA)

- Tresa Pollock, Ph.D., chair of the Materials Department at the University of California –

- Santa Barbara

- Alton D. Romig, Ph.D., executive officer of the National Academy of Engineering and

- former vice president and general manager of Advanced Development Programs

- Engineering and Advanced Systems, known as Skunk Works, for Lockheed Martin

- Aeronautics

- Alan Taub, Ph.D., professor of materials science and engineering at the University of

- Michigan

The challenge partners were grateful for the time and commitment of this group of individuals who played a critical role in achieving the ambitious goals set by the Head Health Challenge III.

Area of Excellence #3: "Continue Community Engagement"

Participating in the Head Health Challenge III leveraged NIST's technical expertise and allowed NIST to do what it does best—conduct measurement science that helps industries overcome barriers to developing new products and manufacture them efficiently and reliably. NIST applied its technical expertise to build materials testing instruments in the laboratory and even created a new rotational impact test in support of the Head Health Challenge III. As NIST learned during the competition, one of the major benefits reported by participants was the opportunity to have their materials assessed by NIST experts. NIST's engagement with the first round winners, as they worked to refine their materials leading up to the announcement of the grand prize winner, yielded robust long-term research partnerships. To help encourage further material design improvements, NIST intends to release to the public large amounts of data generated from tests on the conventional baseline materials.

There is significant opportunity to develop new designs and techniques for testing the performance of soft materials used in protective gear and other applications. What NIST has learned from the testing during this challenge will help inform future standards for the performance of such gear. NIST's new testing device developed for this challenge already has provided valuable data to the Head Health Challenge III participants, and will enable the development of future standards for new generations of protective equipment for athletes, first responders, soldiers and others.

NIST staff continue to provide data from their unique rotational impact test facility for the Challenge III participants. In addition, the NIST facility will be central to a new research effort established with NIST's materials science center of excellence, CHiMAD, which brings together Northwestern University, the University of Chicago and Argonne National Laboratory to accelerate materials design and deployment. The research effort will advance models used to predict the performance of impact-mitigating materials under complex impact conditions, and lead to design rules for new materials development. NIST also has engaged with the challenge community and other stakeholders through a series of workshops aimed at identifying key measurement challenges and standards requirements for head protection tests.

Challenge Type: Scientific, Technology

The Head Health Challenge III excelled at spurring the creation of innovative impact-absorbing materials that can increase protection for athletes, warfighters and civilians. The five finalist teams demonstrated a range of materials that met rigorous technical criteria, from a patented honeycomb material to spring-like fibers. The finalist teams had the opportunity to compete for the grand prize after an additional year and a half further improving their advanced materials to respond in sophisticated testing protocols, under increasing amounts of force and including a new rotational test designed by NIST.

The winning entry reduced certain measures of impact by more than 70 percent when compared with baseline foam material that has been commonly used in protective gear, and the material's middle layer of absorbent posts sandwiched between foam helps reduce the shear forces that can cause rotational injuries. The winning concept also can be fine-tuned to a variety of impact environments and adapted to different body types and applications. One of the co-winners, 6D Helmets has recently announced that the material it developed and improved for the challenge has been deployed in several of their helmet products for bicyclists and motocross sports.

After the challenge, NIST and a representative from the winning team testified about its purpose and outcomes before the House Subcommittee on Research and Technology. The hearing focused on Head Health Challenge III, which provided a catalyst for broader discussion of how prize competitions can be used to successfully address national priorities in science and technology.

Legal Authority

America COMPETES Act